Call Us: +86 15954941919 interested in Contact Us? Mail us now

English

Call Us: +86 15954941919 interested in Contact Us? Mail us now

English

A hydraulic cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or swinging motion) . It has simple structure and reliable operation. When using it to realize reciprocating motion, the reduction device can be omitted, and there is no transmission gap, and the movement is stable, so it is widely used in various mechanical hydraulic systems . The output force of the hydraulic cylinder is proportional to the effective area of the piston and the pressure difference on both sides; the hydraulic cylinder is basically composed of a cylinder barrel and a cylinder head , a piston and a piston rod , a sealing device , a buffer device and an exhaust device . Buffers and exhausts are application specific, other devices are essential.

Hydraulic cylinder is an executive element in hydraulic transmission system , it is an energy conversion device that converts hydraulic energy into mechanical energy. The hydraulic motor realizes the continuous rotary motion, while the hydraulic cylinder realizes the reciprocating motion. There are three types of hydraulic cylinders: piston cylinder, plunger cylinder and swing cylinder. Piston cylinder and plunger cylinder realize reciprocating linear motion, output speed and thrust, and swing cylinder realizes reciprocating swing, output angular velocity (speed) and torque. In addition to being used individually, hydraulic cylinders can also be used in combination of two or more or in combination with other mechanisms. to perform special functions. The hydraulic cylinder is simple in structure and reliable in operation, and has been widely used in the hydraulic system of machine tools.

There are various structural forms of hydraulic cylinders, and there are many classification methods: according to the movement mode, it can be divided into linear reciprocating motion type and rotary swing type; according to the effect of hydraulic pressure, it can be divided into single-acting type and double-acting type; The form can be divided into piston type, plunger type, multi-stage telescopic sleeve type, rack and pinion type, etc.; according to the installation form, it can be divided into tie rod, earring, foot, hinge shaft, etc.; according to the pressure level, it can be divided into 16Mpa, 25Mpa , 31.5Mpa, etc.

Single-rod hydraulic cylinders only have a piston rod at one end. As shown in Figure 1 is a single-piston hydraulic cylinder. Both the inlet and outlet ports A and B at both ends can pass pressure oil or return oil to achieve bidirectional movement, so it is called a double-acting cylinder.

figure 1

The piston can only move in one direction, and the movement in the opposite direction needs to be done by external force. However, its stroke is generally larger than that of a piston hydraulic cylinder.

Piston hydraulic cylinders can be divided into two types: single rod type and double rod type. The fixing methods are fixed by the cylinder body and fixed by the piston rod. According to the effect of hydraulic pressure, there are single-acting type and double-acting type. In a single-acting hydraulic cylinder, the pressure oil is only supplied to one cavity of the hydraulic cylinder, and the hydraulic pressure makes the cylinder move in one direction, and the opposite direction movement is realized by external force (such as spring force , self - weight or external load, etc.); The movement of the piston in the two directions of the action hydraulic cylinder is completed by the action of hydraulic pressure through the alternate oil intake of the two cavities.

Figure 2 shows a schematic diagram of a single-rod double-acting piston hydraulic cylinder. It is only provided with a piston rod on one side of the piston , so the effective working areas of the two chambers are different. When the oil supply amount is the same, different cavities enter oil, and the movement speed of the piston is different; when the load force to be overcome is the same, different cavities enter oil, and the required oil supply pressure is different, or after the system pressure is set, the sanitation The load force that can be overcome by the hydraulic cylinder of the garbage truck in two directions is different.

figure 2

(1) The plunger hydraulic cylinder is a single-acting hydraulic cylinder, which can only move in one direction by hydraulic pressure, and the return stroke of the plunger depends on other external forces or the self-weight of the plunger;

(2) The plunger is only supported by the cylinder liner and not in contact with the cylinder liner, so the cylinder liner is very easy to process, so it is suitable for long-stroke hydraulic cylinders;

(3) The plunger is always under pressure during operation, so it must have sufficient rigidity;

(4) The weight of the plunger is often large, and it is easy to sag due to its own weight when placed horizontally, resulting in the wear of the seal and the guide unilateral, so it is more advantageous to use it vertically.

The telescopic hydraulic cylinder has two or more stages of pistons. The order of the extension of the piston in the telescopic hydraulic cylinder is from large to small, while the order of no-load retraction is generally from small to large. The telescopic cylinder can achieve a longer stroke, while the retracted length is shorter and the structure is more compact. Such hydraulic cylinders are often used in construction machinery and agricultural machinery. There are multiple pistons that move at one time. When each piston moves successively, its output speed and output force change.

Double acting single piston rod hydraulic cylinder

The oscillating hydraulic cylinder is an executive element that outputs torque and realizes reciprocating motion . There are several forms such as single blade, double blade and spiral swing. Vane type: The stator block is fixed on the cylinder, and the vane and the rotor are connected together. According to the oil inlet direction, the vanes will drive the rotor to swing back and forth. The helical swing type is divided into two types: single helix swing and double helix. Now the double helix is more commonly used. The linear motion of the piston in the hydraulic cylinder of the two helical pairs is converted into a compound motion of linear motion and self-rotation motion, thereby realizing the swing motion.

In the hydraulic system, the hydraulic cylinder is used to drive the mechanism with a certain quality. When the hydraulic cylinder moves to the end of the stroke, it has a large kinetic energy. If the deceleration treatment is not performed, the hydraulic cylinder piston and the cylinder head will have a mechanical collision, resulting in impact, noise, etc. destructive. In order to alleviate and prevent the occurrence of such hazards, a deceleration device can be arranged in the hydraulic circuit or a buffer device can be arranged in the cylinder.

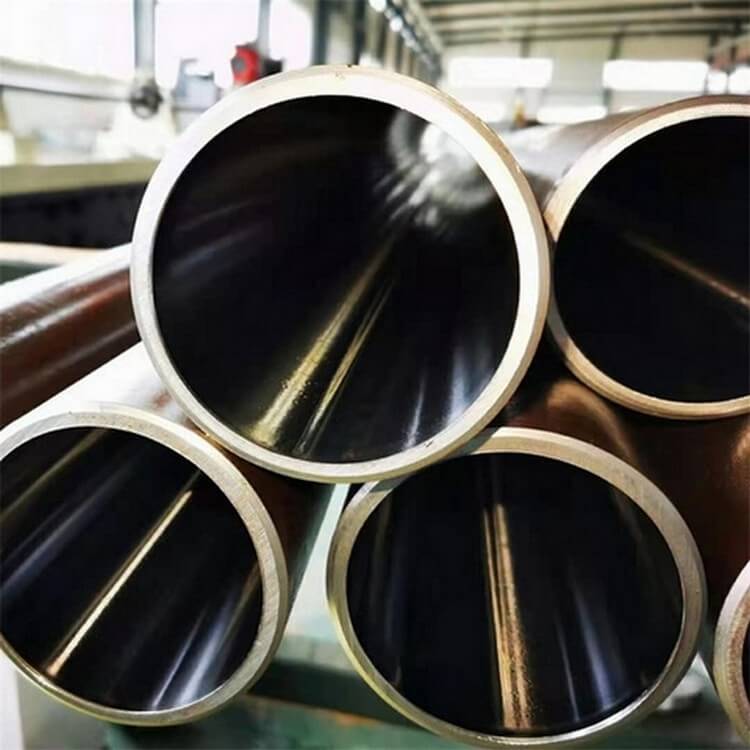

As the main components of hydraulic cylinders, mining single pillars, hydraulic supports , gun barrels and other products, the quality of the cylinder barrel directly affects the life and reliability of the entire product. The cylinder has high processing requirements, and its inner surface roughness is required to be Ra0.4 ~ 0.8&um, and the requirements for coaxiality and wear resistance are strict. The basic feature of the cylinder barrel is deep hole machining , which has always troubled the processing personnel.

The rolling process, because the surface layer has residual compressive stress on the surface, helps to seal the tiny cracks on the surface and hinders the expansion of erosion. Thereby, the corrosion resistance of the surface can be improved, and the generation or expansion of fatigue cracks can be delayed, thereby improving the fatigue strength of the cylinder. Through rolling forming, a layer of cold work hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the cylinder and avoiding burns caused by grinding. After rolling, the reduction of surface roughness value can improve the fit properties.

The oil cylinder is the most important part of construction machinery. The traditional processing method is: broaching cylinder block - fine boring cylinder block - grinding cylinder block. The rolling method is: broaching cylinder block - fine boring cylinder block - rolling cylinder block, the process is 3 parts, but the time comparison: grinding cylinder block 1 meter in about 1-2 days, rolling The cylinder body is 1 meter in about 10-30 minutes. Input comparison: grinder or quilting machine (tens of thousands - millions), rolling knives (1 thousand - tens of thousands). After rolling, the surface roughness of the hole is reduced from Ra3.2-6.3um to Ra0.4-0.8&um before rolling, the surface hardness of the hole is increased by about 30%, and the fatigue strength of the inner surface of the cylinder is increased by 25%. The service life of the oil cylinder is increased by 2 to 3 times if only the influence of the cylinder is considered, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. The above data shows that the rolling process is efficient and can greatly improve the surface quality of the cylinder.

After the cylinder is rolled, there are no sharp tiny edges on the surface, and long-term motion friction will not damage the seal ring or seal, which is particularly important in the hydraulic industry.

Hydraulic cylinders are actuators in hydraulic systems that convert hydraulic energy into mechanical energy. The faults can be basically summarized as hydraulic cylinder malfunction, inability to push the load, and piston slippage or crawling. It is not uncommon for the equipment to stop due to the failure of the hydraulic cylinder. Therefore, attention should be paid to the fault diagnosis and use and maintenance of the hydraulic cylinder.

1. Fault diagnosis and treatment

1. Malfunction or malfunction

The reasons and solutions are as follows:

(1) The valve core is stuck or the valve hole is blocked. When the flow valve or directional valve spool is stuck or the valve hole is blocked, the hydraulic cylinder is prone to malfunction or malfunction. At this time, you should check the contamination of the oil; check whether the dirt or colloidal sediment is stuck on the valve core or block the valve hole; check the wear of the valve body, clean and replace the system filter, clean the oil tank, and replace the hydraulic medium.

(2) The piston rod and the cylinder are stuck or the hydraulic cylinder is blocked. At this time, no matter how it is operated, the hydraulic cylinder does not move or moves very little. At this time, you should check whether the seal of the piston and piston rod is too tight, whether there is dirt and colloidal deposits: whether the axis line of the piston rod and the cylinder barrel is aligned, whether the wearing parts and seals are invalid, and whether the load is too high big.

(3) The control pressure of the hydraulic system is too low. The throttling resistance in the control pipeline may be too large, the flow valve is not properly adjusted, the control pressure is not suitable, and the pressure source is disturbed. At this time, the control pressure source should be checked to ensure that the pressure is adjusted to the specified value of the system.

(4) Air enters into the hydraulic system. Mainly because there are leaks in the system. At this time, check the liquid level of the hydraulic oil tank, the seals and pipe joints on the suction side of the hydraulic pump, and whether the oil suction strainer is too dirty. If so, the hydraulic oil should be replenished , the seals and pipe joints should be treated, and the coarse filter element should be cleaned or replaced.

(5) The initial action of the hydraulic cylinder is slow. When the temperature is low, the viscosity of the hydraulic oil is high and the fluidity is poor, resulting in the slow action of the hydraulic cylinder. The improvement method is to replace the hydraulic oil with better viscosity-temperature performance. At low temperature, the oil temperature at startup can be increased with the help of a heater or by the machine itself. The normal working oil temperature of the system should be maintained at about 40 °C.

2, can not drive the load when working

Mainly manifested as inaccurate piston rod parking, insufficient thrust, speed drop, unstable work, etc. The reasons are:

(1) Internal leakage of hydraulic cylinder. The internal leakage of the hydraulic cylinder includes the leakage caused by the excessive wear of the hydraulic cylinder block seal, the piston rod and the sealing cover seal and the piston seal.

The reason for the seal leakage between the piston rod and the sealing cover is that the seal is wrinkled, squeezed, torn, worn, aged, deteriorated, deformed, etc. At this time, a new seal should be replaced.

The main causes of excessive piston seal wear are improper adjustment of the speed control valve, resulting in excessive back pressure and improper seal installation or hydraulic oil contamination. The second is the entry of foreign objects during assembly and the poor quality of the sealing material . The consequence is that the action is slow and powerless, and in severe cases, the piston and cylinder can be damaged, and the phenomenon of "pulling the cylinder" occurs. The treatment method is to adjust the speed control valve, and make necessary operations and improvements according to the installation instructions.

(2) The hydraulic circuit leaks. Including leaks in valves and hydraulic lines. The maintenance method is to check and eliminate the leakage of the hydraulic connection pipeline by operating the reversing valve .

(3) The hydraulic oil is bypassed back to the oil tank through the relief valve . If the overflow valve enters the dirt and jams the valve core, the overflow valve is normally open, and the hydraulic oil will flow directly back to the oil tank through the bypass of the overflow valve, resulting in no oil entering the hydraulic cylinder. If the load is too large, although the regulating pressure of the relief valve has reached the maximum rated value, the hydraulic cylinder still cannot get the thrust required for continuous action and will not act. If the adjustment pressure is low, the vertebral force required for still loading cannot be achieved due to insufficient pressure, which is manifested as insufficient thrust. At this time, the relief valve should be checked and adjusted.

3. Piston slipping or crawling

Hydraulic cylinder piston slippage or crawling will make the hydraulic cylinder work unstable. The main reasons are as follows:

(1) The inside of the hydraulic cylinder is stagnant. The internal parts of the hydraulic cylinder are improperly assembled, deformed, worn or the shape and position tolerance exceeds the limit, and the action resistance is too large, so that the piston speed of the hydraulic cylinder changes with the stroke position, causing slippage or crawling. Most of the reasons are due to poor assembly quality of the parts, scars on the surface or iron filings generated by sintering, which increases the resistance and reduces the speed. For example: the piston and the piston rod are not concentric or the piston rod is bent, the hydraulic cylinder or the piston rod is offset from the installation position of the guide rail, the sealing ring is too tight or too loose, etc. The solution is to re-repair or adjust, replace damaged parts and remove iron filings.

(2) The lubrication is poor or the bore diameter of the hydraulic cylinder is out of tolerance. Because there is relative movement between the piston and the cylinder, the guide rail and the piston rod, if the lubrication is poor or the bore diameter of the hydraulic cylinder is out of tolerance, the wear will be aggravated, and the linearity of the center line of the cylinder will be reduced. In this way, when the piston works in the hydraulic cylinder, the frictional resistance will be large and small, resulting in slippage or crawling. The elimination method is to grind the hydraulic cylinder first, then prepare the piston according to the matching requirements, grind the piston rod, and configure the guide sleeve.

(3) The hydraulic pump or hydraulic cylinder enters the air. Compression or expansion of air can cause the piston to slip or crawl. The elimination measures are to check the hydraulic pump, set up a special exhaust device, and quickly operate the full stroke to exhaust several times.

(4) The quality of seals is directly related to slippage or crawling. When the O-ring is used under low pressure, compared with the U-shaped sealing ring, due to the higher surface pressure and the large difference between the dynamic and static frictional resistance, it is easy to cause slippage or crawling; the surface pressure of the U-shaped sealing ring increases with the pressure. If it increases, although the sealing effect is also improved accordingly, the difference between the dynamic and static friction resistance also becomes larger, and the internal pressure increases, which affects the elasticity of the rubber. Due to the increase in the contact resistance of the lip, the sealing ring will overturn and the lip will elongate. It is also easy to cause slippage or crawling. In order to prevent it from tipping over, a support ring can be used to keep it stable.

4. The adverse consequences of scratches on the surface of the inner hole of the hydraulic cylinder and the quick repair method

① The material chips extruded from the scratched groove will embed into the seal, which may cause new scratches in the scratched area while damaging the working part of the seal during operation.

② The surface roughness of the inner wall of the cylinder is deteriorated , the friction force is increased, and crawling is easy to occur.

③ Increase the internal leakage of the hydraulic cylinder and reduce the working efficiency of the hydraulic cylinder. The main reasons for scratches on the surface of the cylinder bore are as follows.

(1) Scars caused when assembling the hydraulic cylinder

① Scar caused by foreign matter mixed in during assembly. Before the total assembly of the hydraulic cylinder, all parts must be fully deburred and cleaned. When the parts are installed with burrs or dirt, foreign matter is easy to embed into the cylinder due to the "strength" and the weight of the parts. wall surface, causing scars.

② Scars in the installation parts When installing the hydraulic cylinder, the parts such as the piston and the cylinder head are of large mass, large size and large inertia. Even if there is a hoisting device to assist in the installation, because the specified fitting clearance is small, no matter what, it will be hard to invest. Therefore, when the end of the piston or the boss of the cylinder head hits the inner surface of the cylinder wall, it is very easy to cause scars. The solution to this problem: For small products with large quantities and large batches, use special assembly guide tools during installation; for heavy, coarse, and large large and medium-sized hydraulic cylinders, only careful and careful operation can be avoided.

③The scars caused by the contacts of the measuring instrument are usually used to measure the inner diameter of the cylinder with an inner diameter dial indicator. The measuring contacts are inserted into the hole wall of the cylinder while rubbing, and the measuring contacts are mostly made of high-hardness wear-resistant cemented carbide. Generally speaking, the slender scratches that are not deep in the measurement are slight and do not affect the running accuracy, but if the size of the measuring rod head is not adjusted properly, the measuring contacts are hard embedded, which will cause more serious scratches. The countermeasure to solve this problem is to measure the length of the adjusted measuring head first. In addition, use a piece of paper tape with holes only at the measuring position to be attached to the inner surface of the cylinder wall, that is, the above-mentioned shape scratches will not be generated. . Slight scratches caused by measurement can generally be wiped off with the back of an old emery cloth or horse dung paper .

(2) Minor running wear marks

① Transfer of scars on the sliding surface of the piston Before the piston is installed, there are scars on the sliding surface, which are not treated and installed intact. These scars will in turn scratch the inner surface of the cylinder wall. Therefore, these scars must be fully trimmed before installation.

② The sintering phenomenon caused by the excessive pressure on the sliding surface of the piston will cause the piston to tilt due to the self-weight of the piston rod, resulting in a different phenomenon, or the pressure on the sliding surface of the piston will rise due to the action of lateral load, which will cause the sintering phenomenon. When designing the hydraulic cylinder, its working conditions must be studied, and sufficient attention must be paid to the length and clearance of the piston and bushing.

③ Peeling of the hard chrome plating on the inner surface of the cylinder It is generally believed that the reasons for the peeling of the hard chrome plating are as follows.

a. The plating layer is not well bonded. The main reasons for the poor adhesion of the electroplating layer are: before electroplating, the degreasing and degreasing treatment of the parts is not sufficient; the surface activation treatment of the parts is not thorough, and the oxide film layer is not removed.

b. The hard lining is worn. The wear of the electroplated hard chromium layer is mostly caused by the grinding action of the friction iron powder of the piston. When there is moisture in the middle, the wear is faster. The corrosion caused by the contact potential difference of the metal only occurs in the part where the piston contacts, and the corrosion occurs in the form of points. As above, the presence of moisture in the middle will promote the development of corrosion. Compared with castings, the contact potential difference of copper alloys is higher, so the corrosion degree of copper alloys is more serious.

c. Corrosion due to contact potential difference . Contact potential difference corrosion is not easy to occur for hydraulic cylinders that run for a long time; it is a common fault for hydraulic cylinders that are not used for a long time.

④ Damage to the piston ring The piston ring is damaged during operation, and its fragments are caught in the sliding part of the piston, causing scratches.

⑤ The material of the sliding part of the piston is sintered and cast piston, which will cause sintering phenomenon when it bears a large lateral load. In this case, the sliding part of the piston should be made of copper alloy or welded with such material.

(3) Foreign matter is mixed in the cylinder

Among the failures of the hydraulic cylinder, the most problematic is that it is difficult to judge when the foreign matter enters the hydraulic cylinder. After foreign matter enters, if a seal with a lip is installed on the outside of the sliding surface of the piston, the lip of the seal can scrape the foreign matter during operation, which is beneficial to avoid scratches. However, the two ends of the piston equipped with the O-ring seal are sliding surfaces, and foreign matter is sandwiched between the sliding surfaces, which is easy to form scars.

There are several ways for foreign objects to enter the tank.

① Foreign matter entering the cylinder

a. Due to the careless opening of the oil port during storage, the condition of receiving foreign objects will occur at all times, which is absolutely not allowed. When storing, it is necessary to inject anti-rust oil or working oil and plug it well.

b. Foreign objects enter when the cylinder is installed. In the place where the installation operation is carried out, the conditions are not good, and foreign objects can enter unconsciously. Therefore, the surroundings of the installation site must be cleaned up, especially the place where the parts are placed must be cleaned so that there is no dirt.

c. There are "burrs" on the parts, or insufficient scrubbing. There are often burrs left during drilling in the oil port on the cylinder head or in the buffer device. Pay attention to it and install it after the sand is removed.

② Foreign matter generated during operation

a. Friction iron powder or iron filings formed due to the tension of the buffer plunger. The mating clearance of the buffer device is very small, and when the lateral load on the piston rod is large, it may cause sintering. These friction iron powders or metal fragments that have fallen off due to sintering will remain in the cylinder.

b. Scar on the inner surface of the cylinder wall. The sliding surface pressure of the piston is high, causing sintering, so the inner surface of the cylinder is squeezed and cracked, and the cracked metal falls off and remains in the cylinder, causing scars.

③ There are various cases of foreign matter entering from the pipeline.

a. Careless when cleaning. When the pipeline is cleaned after installation, it should not pass through the cylinder body, and a bypass pipeline must be installed in front of the oil port of the cylinder body. this point is very important. Otherwise, the foreign matter in the pipeline will enter the cylinder. Once it enters, it will be difficult to remove it, and instead it will become a foreign matter being transported into the cylinder. Furthermore, when cleaning, consider the method of removing foreign objects that have entered during the installation of the pipeline. In addition, for corrosion in the pipe, procedures such as pickling should be performed before the pipe is installed, and the rust must be completely removed.

b. Chips formed during pipe processing. After the pipe has been cut to length, there should be no residue left during the deburring operation at both ends. In addition, placing steel pipes near the site where the welding pipeline operation is performed is the cause of the mixing of welding foreign matter. For pipes placed near the welding operation site, the nozzles should be sealed. It must also be noted that the fitting material should be fully stocked on a dust-free workbench.

c. The sealing belt enters the cylinder. As a simple sealing material , PTFE plastic sealing tape is often used in installation and inspection. If the winding method of linear and tape-shaped sealing materials is incorrect, the sealing tape will be cut off and enter the cylinder. The linear belt seal will not have any effect on the winding of the sliding part, but it will cause the check valve of the cylinder to malfunction or cause the buffer regulating valve to be unable to be adjusted to the end; for the circuit, it may cause the reversing valve , overflow Failure of valve and pressure reducing valve action.

The traditional repair method is to carry out outsourcing repair after disassembly of the damaged parts, or to carry out brush plating or overall scraping of the surface. The repair cycle of the hydraulic cylinder block is long and the repair cost is high.

Repair process:

1. Bake the scratched parts with oxygen-acetylene flame (control the temperature and avoid surface annealing), bake out the oil that has permeated the metal surface all the year round, and bake until there are no sparks.

2. Treat the scratched parts with an angle grinder to a depth of more than 1 mm, and grind out grooves along the guide rails, preferably dovetail grooves. Drill holes at both ends of the scratch to deepen and change the force.

3. Clean the surface with absorbent cotton dipped in acetone or absolute ethanol .

4. Apply the metal repair material to the scratched surface; the first layer should be thin, evenly and fully cover the scratched surface to ensure the best bonding between the material and the metal surface, and then apply the material to the entire repaired part and press repeatedly. Make sure the material is filled to the desired thickness, slightly higher than the rail surface.

5. It takes 24 hours for the material to fully achieve various properties at 24°C. In order to save time, the temperature can be increased by using a halogen tungsten lamp . Every 11°C increase in temperature, the curing time will be shortened by half, and the optimal curing temperature is 70°C.

6. After the material is cured, use a fine grindstone or a scraper to repair and level the material above the surface of the guide rail, and the construction is completed.

In the hydraulic cylinder, the cylinder is not only one of the main components, but also one of the indispensable components. Therefore, in order to be familiar with the cylinder tube, the cylinder tube in the hydraulic cylinder

Generally speaking, the structure of the hydraulic cylinder is mainly related to the materials used and the working pressure. In addition, there is a corresponding relationship between the use of materials and working pressure. Different pressure levels correspond to different materials. Therefore, under different materials used, the structure of the cylinder is different.

The choice of cylinder inner diameter is mainly calculated and determined according to the load requirements, and then the one that is close to the standard size is selected. For the safety factor, it is mainly required to be reasonable, and the yield and tensile strength limit values are calculated. Therefore, as long as these two requirements can be met, the safety factor of the cylinder can be considered acceptable.

For the seal on the hydraulic cylinder, the main requirement is to have a good sealing effect and prevent leakage. Therefore, in order to avoid this problem, you can check the dimensional tolerance and shape tolerance of the cylinder, whether it meets the technical requirements, so that preventive work can be done in advance. In addition, you can also check whether there are pull marks on the surface, if there are, you should deal with it in time